Tutorial:Production line

This article describes the basics of setting up production lines, how to read the UI of buildings (such as input and output item rates), and how to calculate building ratios.

For more information on planning a production line, see Tutorial:Production line design tips.

Reading building interfaces

A simple production line involves Miner → Smelter → Constructor → Storage Container. The example shows the buildings' UI, which can be accessed by approaching and interacting E with each building. In this example, each machine's item production matches up perfectly with item consumption (marked in red) making a 1:1 ratio.

Miner

A Miner extracts ore at a rate that depends on both Resource Node's purity and the Miner's mark. The Resource Node's purity, either impure, normal, or pure is fixed based on its location on the map. Higher marks of Miners can be unlocked in later Milestones, which have a higher extraction rate. In this example, the Miner Mk.1 extracts 30 Iron Ore/min from the Resource Node below it.

Smelter

A Smelter smelts ore into ingots. In the above example, 1 Iron Ore is consumed to produce 1 Iron Ingot. The smelting of one ore takes 2 seconds.

Constructor

A Constructor processes the input into useful parts. In the above example, 3 Iron Ingots are consumed to craft 2 Iron Plates.

Per-cycle and per-minute rates

Each building shows two rates: per crafting cycle and per minute. The Constructor in the above example has the following rates:

Per-cycle values are shown in bold text. The cycle duration is shown in the middle of the UI, under a timer icon.

- 3 Iron Ingots are consumed per cycle

- 2 Iron Plates are produced per cycle

- Crafting cycle duration is 6 seconds

Therefore, each Iron Plate takes 1.5 Ingots to craft (3 Ingots make 2 Plates).

These per-cycle values are useful for determing item costs. However, in automated setups, it is easier to use per-minute values instead, shown in smaller, orange numbers below the bold text.

- 30 Iron Ingots are consumed per minute

- 20 Iron Plates are produced per minute

Conveyor Belt

Conveyor Belts automatically transport items from one building to the next, removing the need for manual labor to move items between machines. Belts have a maximum item/min flow rate depending on the belt's mark. If a higher item flow rate is required, consider using higher marks of Conveyor Belts, or constructing multiple parallel belts. Else, the entire production line will slow down due to insufficient item flow.

Storage Container

The Storage Container in the above example is optional. Its purpose is to store and buffer produced items so that the machines before it can run smoothly. Most production buildings can only store up to one stack of items in its output slot, and once it is full, the machine stops.

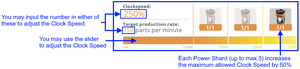

Overclocking

The production speed of machines can be altered with overclocking, which will be discussed in the section below.

Splitting and merging

Production chains rarely work in a 1:1 crafting ratio; the example shown in the previous section is a special case. If there is a mismatch in the buildings' ratio, the entire chain is slowed down proportionally to the slowest element in the chain. This reduces the efficiency and should be avoided.

The term 'Efficiency' is used to describe the uptime of a machine, usually denoted in percentage (%). Efficiency is indicated in the lower right of each machine's UI.

To achieve 100% efficiency, the input rate should be greater or equal to the consumption rate. If more items/min are required, build more machines and use Mergers to bring these items onto a single belt. If there are too many items/min are being input, consider using Splitters to send items into multiple machines.

Miner

A Miner Mk.1 on a normal Copper node extracts 60 Copper Ore/min.

Smelter

A Smelter consumes 30 Copper Ore/min. To consume the 60 Ore/min produced by the Miner, build two Smelters and use a Splitter to split the Conveyor Belt two ways ( 60 / 30 = 2 )

If only one Smelter is built, the Copper Ore produced by the Miner will not be consumed fast enough, and they will backlog into the Miner and causing it to run at only 50% of the time. This is equivalent to 50% efficiency.

Each Smelter produces 30 Copper Ingots/min.

Constructor (Wire)

Each Constructor consumes 15 Copper Ingots/min. Similarly, split each Copper Ingot belt two ways, which can supply up to four Constructors.

30 / 15 = 2 (each Smelter output belt split into two)

2 x 2 = 4 (two Smelters support four Constructors)

Each Constructor produces 30 Wire/min.

Constructor (Cable)

Each Constructor consumes 60 Wire/min. Two Wire Constructors are required to supply one Cable Constructor. Combine the output of two Constructors using a Merger.

30 * 2 = 60

If only one Wire Constructor is connected to a Cable Constructor, the latter will only run 50% of the time due to insufficient input rate. This is equivalent to 50% efficiency.

Each Constructor produces 30 Cable/min.

Conveyor Belt

Conveyor Belt Mk.1 can only transport 60 items/min. In the above example, the belt carrying Copper Ores after the Miner, and the belts transporting Wires after the Mergers are operating at their maximum capacity.

Storage Container

A Storage Container is used to store stacks of items. Avoid mixing items in Storage Containers, as they have an output that can be used to further automate your production line and mixed items can cause your production to jam. A Merger is used to merge two Wire belts into one before the Container to eliminate the need for two Wire Containers.

Overclocking and Flow Rate

As the number of Resource Nodes in the world is finite, there is a hard limit on the total extraction rate. To maximize the potential of a Resource Node, Miners can be Overclocked. The overclocking ability can be researched in MAM via Power Slugs.

Miner

The Miner Mk.1 on a normal Iron node in the above example is overclocked to 250% (x 2.5 speed), hence it extracts 150 Iron Ore/min (60 x 2.5 = 150)

Smelter

Each Smelter consumes 30 Iron Ore/min to yield 30 Iron Ingot/min. Five Smelters should be built to fully utilize the extracted Ore. (150 / 30 = 5)

Conveyor Belt

Conveyor Belt Mk.1 is not fast enough (60 items/min) to pull out all the ore extracted by the overclocked Miner (150 items/min), thus higher marks of the belt are required. Else, the Miner will only run at 40% Efficiency and not at its overclocked potential.

Conveyor Belt Mk.3 (270 items/min) can handle the 150 items/min flow rate and should be built right after the Miner. Conveyor Belt Mk.2 (120 items/min) and Conveyor Belt Mk.1 (60 items/min) are then used as items split off the Conveyor Belt Mk.3 line. Alternatively, all belts can be built with Conveyor Belt Mk.3, if there are sufficient materials to do so.

Manifold

Splitters are organised in a manifold, where each split sends items off the main belt onto belts into the Constructors. The main belt will begin sending items 50/50 down the first split off line, and as the Constructor backfills the split off line will only consume the 30 Iron Ore/min (as consumed by the Smelter). The last Splitter at the far left is optional; it is built for future expansions, when higher marks of Miner are unlocked.

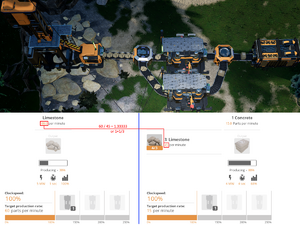

Fractions and decimals

There are many occasions where the building ratio doesn't end up as whole numbers. The Limestone -> Concrete setup is the first production chain that contains a fractional ratio:

60 / 45 = 1.333 or 1+1/3

The Limestone produced by a normal Miner can support one and a third Constructors.

Below are approaches to solve this issue:

Build more machines

Exceeding requirements continues to work without issue. Building two constructors will give both approximately 33% idle time (aka 67% Efficiency). In general, any decimal building ratio can be rounded up to the next integer, for example:

60 / 45 = 1.333 -> 2

400 / 30 = 13.33 -> 14

100 / 110 = 0.909 -> 1

If both Constructors are not underclocked they will just run and stop intermittently, but continue to convert 60 Limestone/min to 20 Concretes/min.

Overclocking and Underclocking

Once overclocking is researched via Power Slugs in the MAM, overclocking and underclocking become available. Power Shards are a limited resource, and take most benefit in raw resource production.

The below show ways to utilise Clock Speed to reach maximum efficiency:

Overclock the Miner

Overclocking the Miner to 150% or 225% will make the ratio an integer.

45 x 2 = 90

90 / 60 = 1.5 (150% overclock, one Miner to two Constructors)45 x 3 = 135

135 / 60 = 2.25 (225% overclock, one Miner to three Constructors)

Overclock the Constructor

Build one Constructor and overclock it to 134%, and all Limestone will be consumed.

Underclock the last machine

Underclocking the second Constructor by either

- Dragging the slider to 34% (Underclocking to 33% loses the additional 0.33% processing speed required)

- Clicking the Clock Speed value (Yellow under label) and typing "33.3334"%

- Clicking the Target Production Rate value (Yellow under label) and typing "15 / 3" (Input fields can handle equations)

Underclock all machines

Underclock both Constructors to 67% has the benefit of improved power saving compared to the previous method. You can examine the power consumption of each underclocked building and add them up.

1.3333 / 2 = 0.6666 = 67%

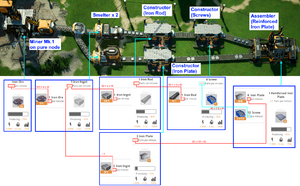

Complex production line

An example Reinforced Iron Plate production line consists of multiple ingredients. In the above image, the buildings are 1:1 showing each stage of the production line with lower efficiency due to incorrect building ratio. Below is an analysis with a walkthrough to correct ratios:

Miner

Miner Mk.1 on a pure Iron node extracts 120 Iron Ore/min. Pure nodes are quite common in Northern Forest and yield double rate. The Conveyor Belt Mk.1 after it is not fast enough and should be replaced with Conveyor Belt Mk.2.

Smelter

A Smelter consumes 30 Iron Ore/min and produces 30 Iron Ingots/min. Therefore the Miner can support four Smelters.

120 / 30 = 4

Dividing Resources

Iron Ingots are divided among Iron Rods and Iron Plates, in an unknown ratio. The top-down method is an effective means to determine how to divide resources: start from the end product, then work backward to its raw ingredients.

Reinforced Iron Plate

The Assembler crafting Reinforced Iron Plates, needs 30 Iron Plates/min and 60 Screws/min. If either of the ingredients faces a shortage, the entire chain will be slowed down.

Iron Plate

Each Iron Plate requires 1.5 Iron Ingots to craft (as described above). Therefore 30 Iron Plates/min requires 45 Iron Ingots/min.

30 * 1.5 = 45

Screw

Each Iron Rod can be crafted into 4 Screws. Therefore 60 Screws/min requires 15 Iron Rods/min.

60 / 4 = 15

Iron Rod

Each Iron Rod requires 1 Iron Ingot. Therefore 15 Iron Rods/min requires 15 Iron Ingots/min.

Math it out

To produce 5 Reinforced Iron Plates/min, the Assembler requires, 45 Iron Ingots/min to produce Iron Plates, and 15 Iron Ingots/min to produce Iron Rods, for a total consumption of 60 Iron Ingots/min.

45 + 15 = 60

By dividing these numbers, the ratio can be simplified to 3:1. Three quarters of the Iron Ingot production is dedicated to Iron Plates, and one quarter dedicated to Iron Rods.

45 : 15 == 3 : 1 (divide both by 15)

The Miner above has the potential to produce 120 Iron Ore/min, which can be crafted into 120 Iron Ingots/min. This can support up to two Assemblers simultaneously.

120 / 60 = 2

After finding the ratio, work from the bottom-up reversing the calculation process, then multiply the setup by 2.

Constructor (Iron Plate)

45 x 2 = 90

90 Iron Ingots/min craft into 60 Iron Plates/min, requiring three Constructors.

90 / 30 = 3

Constructor (Iron Rod)

15 x 2 = 30

30 Iron Ingots/min craft into 30 Iron Rods/min, requiring two Constructors.

30 / 15 = 2

Constructor (Screw)

60 x 2 = 120

30 Iron Rods/min craft into 120 Screws/min, requiring three Constructors.

120 / 40 = 3

Assembler (Reinforced Iron Plate)

Two Assemblers are required to craft the Reinforced Iron Plate.

Conveyor Belt

Splitters and Mergers distribute items as required. Identify belts carrying more than 60 items/min, and construct them with Conveyor Belt Mk.2 or above.

Online tools

Online tools can be used to great extent to lay out the production lines of any item using desired alternate recipes.

| ||||||||||||||||||||||||||||||||