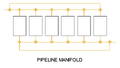

Pipeline manifold

A pipeline manifold (a.k.a. pipe header) is an arrangement of Pipelines and Pipeline Junction Crosses in a series (that is, one after another), usually parallel to the arrangement of buildings, and often supplemented by a loopback pipe.

Because Pipelines have no predefined direction of flow, the system balances itself automatically, as long as there is sufficient fluid supply and throughput limitations are not exceeded. It behaves differently than a conveyor manifold, although both share similar properties. Unlike with conveyors, you cannot construct a "pipeline balancer."

Junction Crosses cause flow to drop if there are too many machines being fed, which you can mitigate using a loopback pipe. It is a secondary pipe split from the main feed pipe which is then merged at the opposite end of the manifold; see the schematic below.

See also

- Conveyor manifold

- Pipeline Manual.pdf, explaining fluid mechanics in details

Gallery

Top view of three Extractors to eight Generators setup, using a common pipeline and two Mk.1 belts, each feed into four generators. The two Mk.1 belts can be merged to a single Mk.2 belt.

Pipe header design is commonly used in Oil-related setup.

Pipe header in Aluminum production.

| ||||||||||||||||||||||||||||||||